Home >

Corporate News >

Win-win Cooperation | NMS Won the “Gold Award for 2022 Strategic Core Customer Innovation Technology Application and Commerce” of Lanxess

Home >

Corporate News >

Win-win Cooperation | NMS Won the “Gold Award for 2022 Strategic Core Customer Innovation Technology Application and Commerce” of Lanxess

2023.03.30

2023.03.30

Recently, Lanxess Chemical (China) Co., Ltd. (hereinafter referred to as “Lanxess”) held 2023 Strategic Partner Award Ceremony with the theme of “Sincere Cooperation for a Better Future of Polyurethane”. At the ceremony, Lanxess Polyurethane Business Department awarded NMS the “2022 Gold Award for Strategic Core Customer Innovation Technology Application and Commerce” and the “2022 Excellent Team for Strategic Core Customer Innovation Technology Application and Manufacturing Management”.

Headquartering in Cologne, Germany, Lanxess is a leading global supplier of special chemical and has 15500 employees & 60 production bases in 33 countries worldwide. Lanxess polyurethane system is a leading global manufacturer of hot poured prepolymers as well as a leading manufacturer of special waterborne polyurethane dispersion, coating system and polyester polyol.

The cooperation between NMS and Lanxess has a long history. In 2007, Lanxess low dissociation products have been applied to high-end screen products of NMS New Technology Material Co., Ltd. (hereinafter referred to as “New Technology”), a subsidiary of NMS. In 2019, New Technology used Lanxess MDI three-component polyurethane material to jointly develop a high-quality MDI polyurethane anti-blocking and wear resistant screen. Since 2022, NMS has signed an annual cooperation agreement with Lanxess, which officially upgrading to a strategic partnership. The cooperation between the two sides has achieved a gradual leap from nil to existence. In addition, its Duracure high wear resistant system material and special material such as ultra-low temperature resistance have been used in NMS screening equipment.

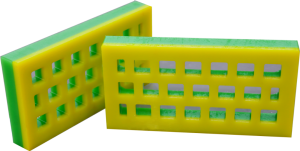

MDI polyurethane screen developed by NMS New Technology and Lanxess

Compared to traditional screen, MDI polyurethane screen has greater wear resistance, better elasticity, low hole blocking rate, higher screening efficiency and longer service life, which can perfectly address the issues like easy hole blocking, low screening efficiency and low wear resistance. Currently, Nanchang New Technology MDI polyurethane screen has been exported to domestic and foreign markets. In 2022, the annual consumption of MDI three-component materials exceeded the 100 tons.

MDI polyurethane screen has been used for 12 months, and the blocking rate is below 15%

As Zhang Zhenglei, President of the Asia Pacific of Lanxess Polyurethane Business Unit, said that from tens of kilograms of samples to the commercialization of 100 tons of MDI polyurethane screen in 2022, the cooperation between the two companies has yielded fruitful results in just four years. After selecting the candidate projects, Lanxess believed that NMS MDI polyurethane project ranks among the top in five categories, including new technology application, commercialization cycle, brand influence, stock forecasting accuracy, product and process control stability. Therefore, it hereby awarded NMS the 2022 Strategic Core Customer Innovation Technology Application and Commerce Gold Award.

Zhang Zhenglei, President of the Asia Pacific of Lanxess Polyurethane Business Unit

Liu Min, Vice President of NMS & General Manager of New Technology, said that the wear-resistant, anti-blocking and screening efficiency of MDI polyurethane screen have been widely praised and gradually recognized by more users. He believed that there would be a broader space for cooperation between the two sides in the future. New Technology would continue to deepen its main business and work together with Lanxess to create and upgrade high-performance polyurethane products, creating better product solutions and services for users.

Liu Min, Vice President of NMS & General Manager of New Technology