Home >

Corporate News >

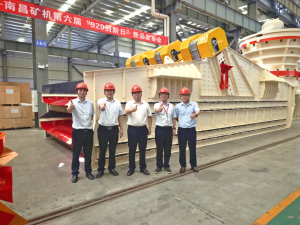

Nanchang Mineral Systems Launches Over Ten New Products at the Sixth “9·29 Innovation Day,” Igniting Passion Across the Company

Home >

Corporate News >

Nanchang Mineral Systems Launches Over Ten New Products at the Sixth “9·29 Innovation Day,” Igniting Passion Across the Company

2024.11.06

2024.11.06

On September 29, Nanchang Mineral Systems held the sixth “9·29 Innovation Day” conference. The event, themed “Innovation Drives Development, Technology Leads the Future,” aimed to stimulate the company’s inherent innovative vitality, accelerate the transformation of technological achievements into productive forces, and inject strong momentum into the sustainable enhancement of industry quality development and customer value.

In his opening speech, Chairman and President Li Shunshan emphasized, “In a rapidly changing market environment, developing new quality productivity is an inherent requirement and important focus for promoting high-quality development. We must continue to excel in innovation, driving the rapid development of new quality productivity. The origin of innovation begins with the emergence of the ‘altruistic’ mindset. When we carry an ‘altruistic heart,’ we face challenges in our work and address customer pain points, leading us to confront difficulties and seek improvements in imperfect situations. With an awareness and intention for innovation, the next step is to take action. We need to create an environment that ‘encourages innovation and tolerates failure,’ actively promoting, praising, and encouraging innovators. Recognizing small improvements, small innovations, and minor inventions will help ignite everyone’s enthusiasm for innovation and foster a culture of creativity. Each person may have varying abilities, but everyone possesses innate potential for innovation, which can be fully developed through learning, training, and practice. Let us join hands to embark on an innovation journey, appreciate the scenery along the way, enjoy the benefits of innovation, and propel Nanchang Mineral Systems toward a brilliant future.”

During the innovation conference, the new product launch showcased 13 new products across three categories: mobile, crushing, and grinding, representing the latest technological achievements in the industry and demonstrating Nanchang Mineral Systems’ leading position and innovative capabilities in the crushing and screening field.

New Mobile Products:

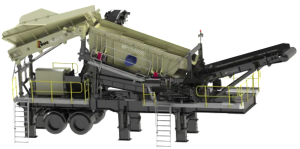

1. MT1315HS-S Track-Mounted Mobile Impact Crushing and Screening Station

The MT1315HS-S Track-Mounted Mobile Impact Crushing and Screening Station is cleverly composed of multiple working modules and can be widely used for crushing and recycling medium-hard, low-abrasion materials. To fully meet customer needs, multiple optional configurations and innovative designs are available to ensure significant improvements in production efficiency. The equipment offers various power options, including external electricity and direct drive, effectively meeting diverse production requirements. It can be equipped with a high-efficiency vibrating screen to produce one or two standard products, and through closed-circuit circulation, large particle materials can be crushed again. Additionally, an independent vibrating screen is designed at the feed end to enhance mud removal, achieving more precise and efficient feeding and mud removal. The integrated PLC control system monitors and controls equipment operation, and with the optional remote communication module, remote control and rental services can be provided.

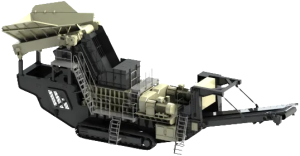

2. MT1616HMC Track-Mounted Hammer Crusher

The MT1616HMC Track-Mounted Hammer Crusher features the latest high-efficiency hammer crusher developed by Nanchang Mineral Systems as its core crushing equipment. Its heavy-duty rotor design ensures a powerful impact crushing force. The high-strength body of the equipment undergoes overall annealing treatment, allowing it to withstand greater impact forces for optimal crushing results. Furthermore, the track-mounted equipment offers multiple configurations for customer choice, such as power options, screening modules, and mud removal methods. Innovative designs for discharge height and maintenance significantly improve maintenance efficiency. This product is widely used in industries like cement, ceramics, and new green building materials and can crush general brittle ores such as limestone, argillaceous siltstone, shale, and gypsum, as well as limestone and clay mixtures.

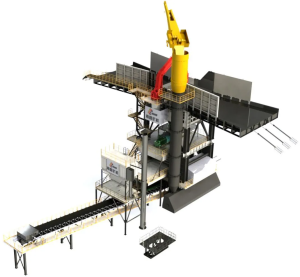

3. MK6275GC/MK60110GC Semi-Mobile Gyratory Crushing Station

The MK6275GC/MK60110GC Semi-Mobile Gyratory Crushing Station is equipped with Nanchang Mineral Systems’ advanced GC series gyratory crushers. The company has successfully developed multiple models of gyratory crushers, with production capacities ranging from 1600 tph to 8000 tph, making it an ideal choice for primary crushing of various rocks and ores, fully meeting different production demands. This crushing station integrates the gyratory crusher, control system, dust removal system, maintenance system, and conveyor system, perfectly catering to the needs for rapid construction and production. Additionally, the semi-mobile crushing station is equipped with a mobile frame compatible with track transport vehicles, allowing for easy relocation of the main body to a new work site by simply removing auxiliary components like the discharge conveyor and truck passage, greatly reducing the transition period and lowering costs.

4. Customized Track-Mounted Mobile Crushing and Screening Station, Customized Tire-Mounted Mobile Crushing and Screening Station, Customized Skid-Mounted Mobile Crushing and Screening Station

Tracked Mobile Crushing and Screening Station

Wheeled Mobile Crushing and Screening Station

Skid-mounted Mobile Crushing and Screening Station

The mobile crushing and screening stations are widely used for coarse, medium, fine crushing, and screening processes in various mines and aggregates. Leveraging Nanchang Mineral Systems’ strong technical team, the company offers rich customization designs and services based on customer site process requirements, covering main machine types and models, power systems, process flows, combinations, and color appearances to precisely meet customer needs and effectively solve their problems. This includes customizing various mobile crushing and screening equipment main machines and power systems, including direct drive diesel engine mode, diesel generator set mode, and external electricity mode, providing independent and multiple equipment combination customization solutions, with options for crushers, metal separators, extreme cold weather kits, and more to adapt to various working conditions.

New Grinding Products:

1. GC5475 Gyratory Crusher

The GC5475 Gyratory Crusher is suitable for primary crushing of various rocks and ores in large projects, featuring large capacity, high efficiency, significant crushing ratio, and energy savings. The equipment has a main motor power of 630 kW, a maximum feed size of 1180 mm, and is equipped with a high-strength frame, integrated alloy steel forged spindle, and automatic lubrication system for the arm, ensuring a solid and durable structure with convenient maintenance. Custom liner design options are also available, offering high adaptability and flexibility.

2. MC800/MC1000 Multi-Cylinder Cone Crusher

The MC800/1000 Multi-Cylinder Cone Crusher features large eccentric distance, high crushing force, high yield, simple operation and maintenance, and low operating costs, making it widely applicable in projects involving metal mines, non-metal mines, and sand and gravel aggregates. The equipment uses an enhanced frame design and high-strength alloy steel forged spindle to crush harder ores; liner options include both standard and thickened designs to better meet customer needs.

3. SC1500 Inertial Cone Crusher

The SC1500 Inertial Cone Crusher is a new energy-saving ultra-fine crushing equipment suitable for various high-hardness materials, featuring a large crushing ratio, energy efficiency, stable technical indicators, and easy operation and installation. Compared to traditional crushers, this equipment does not have a fixed CSS, allowing for smaller particle size crushing and stronger overload and metal inclusion capabilities, providing significant technical advantages in the crushing of ores containing metallic materials and metallurgical slag. It is widely applicable in large metal mines, non-metal mines, and for secondary and tertiary crushing in aggregate and cement production lines.

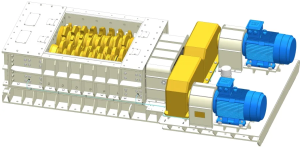

4. RC0515 Tooth Roller Crusher

The RC0515 Tooth Roller Crusher utilizes the property that the compressive strength of minerals is greater than shear strength, and shear strength is greater than tensile strength, mainly crushing materials by applying shear and tensile forces, effectively reducing the energy consumption in the crushing process. The equipment operates with minimal vibration and noise due to the absence of an active vibration source, enhancing its reliability. It features a special self-cleaning mechanism, showing strong adaptability to sticky materials and preventing blockages. The RC0515 Tooth Roller Crusher can be widely used in coal, mining, metallurgy, building materials, and other industries for crushing medium to low hardness materials, such as coal gangue, sintered ore, limestone, bauxite, clay, chemical raw materials, and tailings recovery.

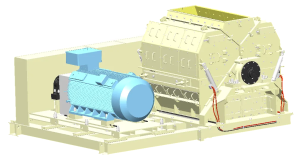

5. HSC1622 Horizontal Sand Making Machine

The HSC1622 Horizontal Sand Making Machine is a new generation product successfully developed by Nanchang Mineral Systems, incorporating the most advanced sand making technology currently available. It is primarily used for sand making operations of medium-hard, low-abrasive materials, featuring high processing capacity, high crushing efficiency, uniform product granularity, and low energy consumption. The HSC1622 is equipped with a 630 kW variable frequency motor and has a maximum feed size of 25 mm. It is also equipped with a new generation intelligent control system that can monitor and warn of key operational parameters in real time, ensuring the equipment operates at its optimal state.

New Screening Products:

1. RS2434 Roller Screen

The RS2434 Roller Screen is suitable for industries such as sand and cement, mining, and coal screening. It can be used for pre-screening and mud removal in sand and cement, transporting ores, and enhancing efficiency in cost reduction transformations on crushing lines. The RS2434 is standardly equipped with an automatic lubrication system, and its motor and reducer are a direct drive structure with no overall vibration, providing stable operation, high reliability, and simple maintenance. The equipment is also configured with PLC remote intelligent control for real-time monitoring of operational conditions and can adjust the number of roller shafts and arrange multiple steps to enhance screening efficiency, while the self-cleaning feature removes sticky materials adhering to the roller surface.

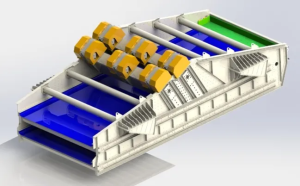

2. 2MES4385-B Box-Type Elliptical Banana Screen

The 2MES4385-B Box-Type Elliptical Banana Screen can be widely used for grading fine particles and sticky materials in industries such as metallurgy, coal, and mining. It can replace existing large box-type banana screens and has advantages in both screening efficiency and processing capacity. The 2MES4385-B utilizes the unique EVB series box vibrator, with no gears inside the casing and independently designed bearing lubrication for the three shafts. It is equipped with imported bearings, has a strong excitation force, is easy to maintain, and has a long service life. The oversized main beam is designed to fit the EVB series box vibrator, with a positioning manufacturing process that undergoes post-weld annealing to eliminate stress; it features an external gearbox with a unique oil route design, greatly enhancing operational stability and lifespan.

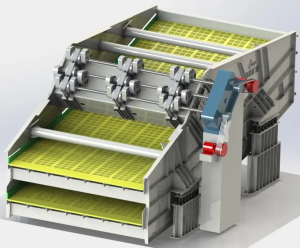

3. 2MLS52120-F Box-Type Tension Screen

The 2MLS52120-F Box-Type Tension Screen can be widely applied for grading fine particles and sticky materials in industries like metallurgy, coal, and mining, commonly used for mud removal before crushing and closed-circuit screening after high-pressure roller processes. The 2MLS52120-F employs the unique VB series box vibrator, standardly equipped with dilute oil lubrication imported bearings, high excitation force, high throwing acceleration, and long service life. The crossbeam is processed with positioning technology, and the welds are polished smoothly and treated with annealing to relieve stress. It uses composite springs to minimize operational noise and enhance reliability, while natural rubber protects the crossbeam and side plates, significantly extending the equipment’s lifespan.

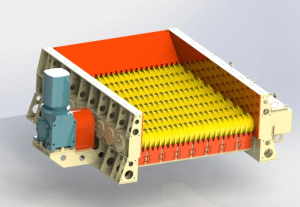

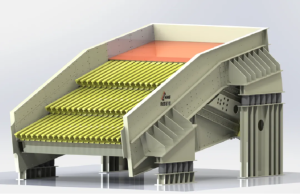

5. MPF3648 Box-Type Bar Screen

The MPF3648 Box-Type Bar Screen is used to feed primary jaw crushers, primary impact crushers, and primary hammer crushers. It can be widely applied in stone, building materials, and metallurgical mining industries, especially suitable for high-load, high-strength, and large-capacity mining conditions. The MPF3648 features an adjustable spacing multi-section bar design, which improves screening efficiency while adapting to various working conditions. The casing adopts a frame beam structure, with side plates connected to beams using high-strength shear bolts, with no welding involved. The crossbeam is made of H-beams, significantly enhancing the equipment’s load-bearing capacity. It features the unique VB series box vibrator, standardly equipped with dilute oil lubrication imported bearings, high excitation force, high throwing acceleration, and long service life, and uses composite springs for low operational noise and high reliability.

To recognize advanced individuals and set an example, the conference held a grand award ceremony for the 2024 Innovation Projects. Award-winning project representatives shared their innovation journeys, insights, and experiences, inspiring more employees to engage in innovation. Additionally, the inspiring speeches from special guests sparked further intellectual exchanges, providing valuable insights and suggestions for Nanchang Mineral Systems’ future development.

To continuously stimulate the company’s innovative vitality, the conference also announced the “2025 ‘Challenge and Lead’ Innovation Topics.” These topics closely align with the practical needs of the company’s innovative development, incorporating the wisdom and suggestions of all employees. The aim is to ignite the enthusiasm and creativity of outstanding teams and individuals through a challenge-and-lead approach, tackling technical difficulties together and advancing technological progress and industrial upgrades. On-site, exceptional teams and individuals eagerly accepted the challenges, showcasing the spirit of responsibility and innovation among employees from Nanchang Mineral Systems. Furthermore, the Ziqingshan Innovation Club of Nanchang Mineral Systems also held an induction ceremony during the conference, marking the club’s commitment to gathering more innovative power to contribute wisdom and strength to the company’s innovative development.

During the Innovation Day event, a “Quality Guardian Action for All” was also conducted. Employees actively participated in on-site product reviews by scanning QR codes to submit identified issues and improvement suggestions. This initiative not only improved product quality but also enhanced employees’ quality awareness and sense of responsibility, fostering a positive atmosphere for everyone to focus on quality and participate in quality management.

Liu Min, Vice President of Nanchang Mineral Systems, pointed out in his summary of the conference: “Nanchang Mineral Systems must unwaveringly create an open and inclusive innovation environment, respect each employee’s individuality, tolerate reasonable mistakes and attempts, and empower teams through decentralization, giving them appropriate flexibility to unleash their internal vitality. We encourage internal questioning and aim to guide employees to grow through trial and error, making innovation a part of our corporate culture. Trusting and relying on employees is essential; we advocate collective wisdom and collaboration. Breaking down internal and external barriers and enhancing cooperation and communication across departments and fields are also crucial. We must avoid sacrificing long-term innovation capabilities for short-term results and may consider adopting a relatively independent management model for innovation teams, ensuring they have enough space and time for in-depth research and development. Additionally, Nanchang Mineral Systems will steadfastly guarantee continuous investment in innovation projects, establishing a scientific, reasonable, and attractive talent policy and mechanism to attract and retain talent, jointly promoting the flourishing development of Nanchang Mineral Systems’ innovation efforts.”

The successful conclusion of the sixth “9·29 Innovation Day” conference marks a significant step for Nanchang Mineral Systems on the path of innovation-driven development. In the future, Nanchang Mineral Systems will continue to uphold the philosophy of “Innovation-Driven Development, Technology Leading the Future,” continually increasing investment in innovation, deepening industry-academia-research cooperation, and accelerating the application of technological achievements to inject continuous momentum into the company’s high-quality development. (Liu Xiaohan)