Home >

Corporate News >

NMS Empowers the Alumina Industry with Advanced Equipment and Leading Technology

Home >

Corporate News >

NMS Empowers the Alumina Industry with Advanced Equipment and Leading Technology

2024.11.29

2024.11.29

Alumina, the primary refined product of bauxite, serves as the foundational material for producing metal aluminum and various alumina products. In recent years, with the continuous increase in global aluminum consumption and the expanding downstream applications of alumina, the industry has maintained a steady growth trend. As the largest producer and consumer of alumina globally, China’s demand for alumina continues to rise. Capitalizing on its profound expertise and technological strengths in crushing and screening, NMS has become the preferred high-performance solution provider for the alumina industry.

NMS offers state-of-the-art crushing and screening equipment and comprehensive solutions tailored to meet the precise crushing and efficient screening requirements of alumina production. Recognizing the importance of technological innovation, NMS consistently invests in research and development to enable efficient production in the alumina industry through high-end equipment and cutting-edge technology. The company’s experienced technical team provides customized solutions, ensuring optimal performance and profitability for clients throughout the production process.

NMS has distinguished itself with its exceptional R&D capabilities, technological innovations, and industry influence. Over the years, the company has achieved numerous milestones, including receiving the Jiangxi Provincial Key New Product Certificate and accolades from the Ministry of Industry and Information Technology, the China Machinery Industry Federation, and other esteemed organizations.

NMS employs 14 core technical experts and 100 R&D personnel, with R&D staff accounting for 15.41% of its workforce. The company holds 511 authorized patents and has participated in formulating 29 national and industry standards as a member of the China Mining Machinery Standardization Technical Committee. NMS has been recognized as a National Specialized and Innovative “Little Giant” Enterprise, a National Intellectual Property Advantage Enterprise, and a Jiangxi Provincial Intelligent Manufacturing Benchmark Enterprise. It also hosts several research facilities, including a national postdoctoral research station, a provincial mineral processing technology innovation center, and a provincial industrial design center.

In 2022, two of NMS’s technologies—the “Hydraulic High-Frequency Screen Technology” and the “Large Single-Cylinder Hydraulic Cone Crusher Technology”—were included in the Ministry of Natural Resources’ “Catalogue of Advanced and Applicable Technologies for Mineral Resource Conservation and Comprehensive Utilization (2022 Edition)”, underscoring the company’s technological leadership. In 2023, the “MSP200 Sand-Making Tower” was awarded the 2022 Jiangxi Provincial Excellent New Product First Prize, and in 2024, the “MC600 Multi-Cylinder Hydraulic Cone Crusher” won the 2023 Jiangxi Provincial Excellent New Product Third Prize.

Leveraging its robust talent pool, NMS has developed the “Flowsheet Designer” process calculation software, filling a critical gap in the domestic industry. Additionally, the company’s Rock Crushing Work Index (Wi) and Rock Abrasion Index (Ai) testing machines have addressed the lack of tools for evaluating mechanical processing indices of parent rocks, providing more scientific and accurate data for equipment selection.

In the realm of intelligent solutions, NMS has partnered with Rockwell Automation to build an IoT-based intelligent operation and maintenance platform. This platform offers real-time equipment data collection, operational status monitoring, remote maintenance guidance, lifecycle management, intelligent data analysis, and predictive analytics, delivering digital solutions and integrated maintenance services that help clients reduce costs and enhance efficiency.

Looking ahead, NMS will continue to deepen its involvement in the alumina industry, innovate and optimize its solutions, and provide more efficient, eco-friendly, and sustainable crushing and screening services. By doing so, the company aims to support the alumina industry’s high-quality development.

Recommended Equipment for Bauxite Crushing and Screening

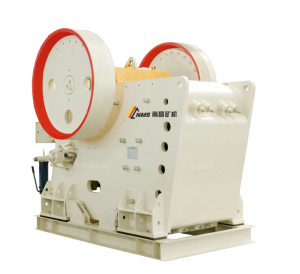

01 Jaw Crusher

The JC series jaw crusher, developed with advanced technology and research insights, features a deep symmetrical crushing chamber design that significantly enhances the crushing ratio. Known for its large crushing capacity, high reliability, sturdy structure, and easy maintenance, the JC series is widely applied in the primary crushing of high-hardness and highly abrasive ores.

02 Cone Crusher

As a co-drafter of industry standards such as “Powerful Cone Crusher JB/T11295-2012” and the national standard “Energy Efficiency Index for Cone Crushers GB/T26965-2011”, NMS produces the CC series single-cylinder cone crusher. Incorporating lamination crushing and automated control technology, the CC series offers features like overload protection, tramp iron protection, and automatic liner wear compensation, delivering exceptional efficiency and adaptability for medium and fine crushing operations.

03 Screens

NMS has played a leading role in drafting the national standard “YKR Circular Vibrating Screen JB/T 6388-2004” and has developed numerous models and specifications based on its extensive application experience in metal mining and aggregate industries.

NMS has played a leading role in drafting the national standard “YKR Circular Vibrating Screen JB/T 6388-2004” and has developed numerous models and specifications based on its extensive application experience in metal mining and aggregate industries.

Both NMS banana screens and box-type linear screens are equipped with VB box-type exciters, offering high excitation force and throwing acceleration. These screens feature SKF or FAG bearings, maintenance-free exciters, and extended service life. Their dual-seal design ensures excellent dustproof performance. The robust screen frame design allows for amplitude adjustment by adding or removing counterweights, providing low noise and high reliability.

04 Feeders

NMS feeders are designed to feed primary jaw crushers, impact crushers, and hammer crushers, making them versatile for applications in stone, building materials, and metallurgical industries.

By offering comprehensive, cutting-edge solutions, NMS continues to empower the alumina industry and drive innovation across the crushing and screening sector.