2024.11.26

2024.11.26

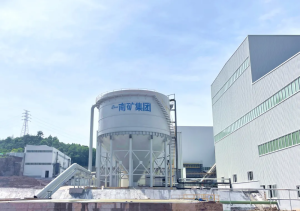

Zhejiang Construction Investment Transportation Infrastructure Group Co., Ltd., a leading enterprise under Zhejiang Construction Investment Group Co., Ltd., has completed the first-phase C-area project of the Cangshan Industrial Cluster in Tiantai County. In this joint venture with Tiantai Transportation Group, the Cangshan Sand and Gravel Aggregate Production Base has been successfully constructed. The 1000 TPH tuff production line at the base has officially commenced operations.

01.Core Equipment

The project boasts a robust lineup of core equipment, with all main equipment meticulously supplied by Nanchang Mineral Systems (NMS). Key equipment includes JC Jaw Crusher, MC Multi-cylinder Cone Crusher, CC Single-cylinder Cone Crusher, VS Vertical Shaft Crusher, YKR Circular Vibrating Screen, ZKR Linear Vibrating Screen, HPF Grizzly Feeder, and GZG Vibrating Feeder.

02.Intelligent Control

The electrical control system and centralized control system for the equipment were tailor-made by Jiangxi NMS Automation Technology Co., Ltd., ensuring precise control and efficient management throughout the production process.

03.Construction and Installation

The production line was constructed and installed by Jiangxi NMS Engineering Co., Ltd., a subsidiary of NMS. To ensure efficient project execution, Jiangxi NMS established a project command center on-site. With a dedicated team and months of relentless effort, the company successfully completed the project, earning high praise and recognition from the client.

04.Advanced Process

The project adopts a “three-stage closed circuit + shaping and sand-making” crushing process, integrating both dry and wet production methods. The raw material is first processed through the jaw crusher for coarse crushing, followed by secondary crushing with the cone crusher, fine crushing with the multi-cylinder cone crusher, and final shaping and sand-making with the vertical shaft crusher. The end products are divided into three specifications: 0-5mm, 5-15mm, and 15-31.5mm.

Considering the raw material characteristics, NMS optimized the production line design by incorporating a washing stage after secondary crushing. This effectively reduces the mud content in the final product and optimizes the gradation of manufactured sand. To allow clients flexibility in adjusting product proportions according to market demands, the project includes a shaping module for 5-31.5mm aggregates and an option to return 5-15mm aggregates for sand-making after screening. Additionally, a high-efficiency wastewater treatment system was installed to recycle water used during production, ensuring an eco-friendly operation.

Upon full operation, the project will efficiently utilize local tuff resources and leverage advanced production techniques to supply high-quality aggregates and manufactured sand to Tiantai County and its surrounding regions. This will inject strong momentum into the region’s socio-economic development, supporting sustainable growth.